SMWALL

01

What is this?

The system SM WALL is an innovative process for the construction of reinforced soil structures by mean of insertion of synthetic armatures. The soil reinforcement technique, consisting in the insertion of armatures comprising both metallic and polymeric bands, deployed in horizontal layers within the ground and anchored to the external retaining wall, either vertical or slanted, is well known in the geo-technical engineering field and several systems based on this principle have been developed.

The SMWALL system differs from other armature systems (metal bands or strips conventionally used) in its use of synthetic, bi-directional armatures in the form of geogrids. (Italian Patent N. 1333029.

The uniqueness of the Equiter system is in its use of geo-grids as armature elements. In reinforced soil, retaining wall structures as those examined here, the system geo-grids allow for the within-ground reinforcement to be more uniform, and give that reinforcement a more effective action when compared to that given by discrete strip or band anchorage systems.

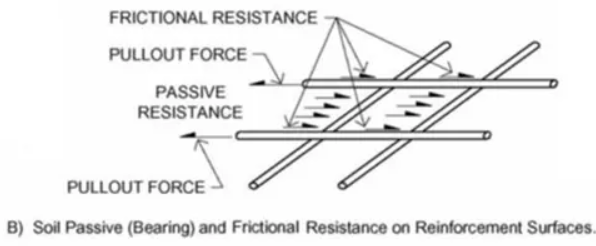

This is due to the presence of transverse lines, running parallel to the retaining wall, which noticeably improve the anchorage characteristics, thus increasing the armatures’ resistance to separation from the soil.

The SMWALL soil reinforcement system is totally composed of prefabricated elements, quick and easy to install, that together with fill-in soil of specific characteristics forms the structure.

The system can be used in several fields of application such as: √ Support walls √ Settling of slopes √ Architectural barriers √ Industrial works √ Motorway platforms √ Railway platforms

02

Benefits

Simplicity and speed of assembly operations thanks to the conformation of the reinforcements and to the efficiency of the anchoring systems to the panels. In fact, after the laying of a layer of geogrid, which reaches the building site wrapped in rollers and which must only be unrolled by spreading it on the ground, and after its connection to the appropriate anchors on the back of the panel, the reinforcement roll remains continuous and it is brought to the upper level as the earth layer increases, to the next anchorage point. In other words, the system allows the use of the same armor to achieve, with a single operation, two or more consecutive levels of internal reinforcement, without the need to bring several separate elements into the site.

High ground anchoring capacity. As widely described above, the two-dimensional structure of the reinforcement, combined with a lower ground thrust thanks to the dynamic interlocking phenomenon, allows to obtain an anchoring capacity to the ground as well as a greater resistance to the extraction considerably greater compared to that guaranteed by other systems with discrete or punctual reinforcements.

03

Constituent elements

The SM WALL system consists of:

Prefabricated panels in reinforced concrete

They are prefabricated concrete panels reinforced with electrowelded mesh having a constant thickness of 14 cm. They are essentially divided into three types: the base panel with a maximum size of 2 x 0.8 m, the standard panel with a size of 2 x 1.6 m and the top panel with variable dimensions in order to follow the project profile and in any case to the maximum equal to 2 x 2.4 m. Weights vary from 0.5 to 1.8 tons and therefore easy handling is guaranteed. The system guarantees excellent performance during installation and assembly as the Equiter panels have a surface greater than that of the panels produced by other competitors on the market, with the advantage of installing a greater quantity of finished structure with the same laying operations.

Synthetic reinforcements

The system involves the exclusive use of CE-marked geogrids in polyester with high tenacity and high elastic modulus with coating against U.V. The ultimate tensile strength of the geogrids is between 20 kN / m and 200 kN / m in the direction of greatest stress (longitudinal uniaxial direction) with a minimum of 25 kN / m in the transverse direction; the elongation at break of the geogrid is less than 14%.

Geogrid / panel connection elements

To allow the reinforcing geogrid to hook onto the panel, f26 steel bars coated with plastic material are used, which are then inserted inside steel rings coated with PVC already embedded in the concrete panel. The connection system, without bolts, is therefore completely isolated from the ground and is therefore free from corrosion phenomena.

Less susceptibility to changes

Less susceptibility to changes in the mechanical characteristics of the earth to be detected. The high ground anchoring capacity of bidirectional reinforcements made up of geogrids allows the use of a wider range of filling terrains and / or a reduction of the overall dimensions of the reinforcements on the back of the artifacts. The resistance of the reinforcements to aggressive environments allows the use of the Equiter technology in combination with stabilization interventions of the survey with lime or cement, further extending the range of land that can be used for the construction of the embankment.

Increased durability

The use of synthetic geogrids as a reinforcement system guarantees the long-term performance of the elements even in chemically very aggressive environments. The reinforcements made of metal strips, while presenting good mechanical characteristics and developing sufficient friction, have often manifested corrosion problems, especially in the presence of aggressive environments or stray currents. Due to the non-uniform nature of the corrosive phenomena, these drawbacks are, however, difficult to manage with sacrificial thicknesses or galvanizing layers. Furthermore, the protection with zinc bath is considerably reduced during the lifetime of the work, even if there are no defects in the galvanizing bath or mechanical damage during installation, which would result in an early damage.

01

02

03